finding loving homes for stray IBM Selectric typewriters

All ball recall!

17 SEP 2023

All of our 3D printed Selectric elements have a date code at the top of the inside wall just below the ceiling:

If the date code is before 13 SEP 2023, the ball has a design flaw which can damage the typewriter. Please don't use these! I'm mailing out replacements for all balls shipped before this date.

So what happened?

In short, I jumped the gun on opening the store, got a bit too excited to cross that threshold after spending months fine tuning and didn't do a proper beta test, trying the balls on as many different Selectrics as I could. When the first orders showed up there was one report of rotate alignment problems but it was quickly worked around by sanding the teeth smooth and adding a bit of grease on the inside. Then the thing I'd been dreading most happened: One of my type balls broke a typewriter. Luckily it was only a slipped rotate tape and we were able to get it sorted out over chat. But when I pulled down my Selectric 1 and tried one of the balls (as I should have months ago) it immediately knocked the rotate tape off the spindle in the carrier.

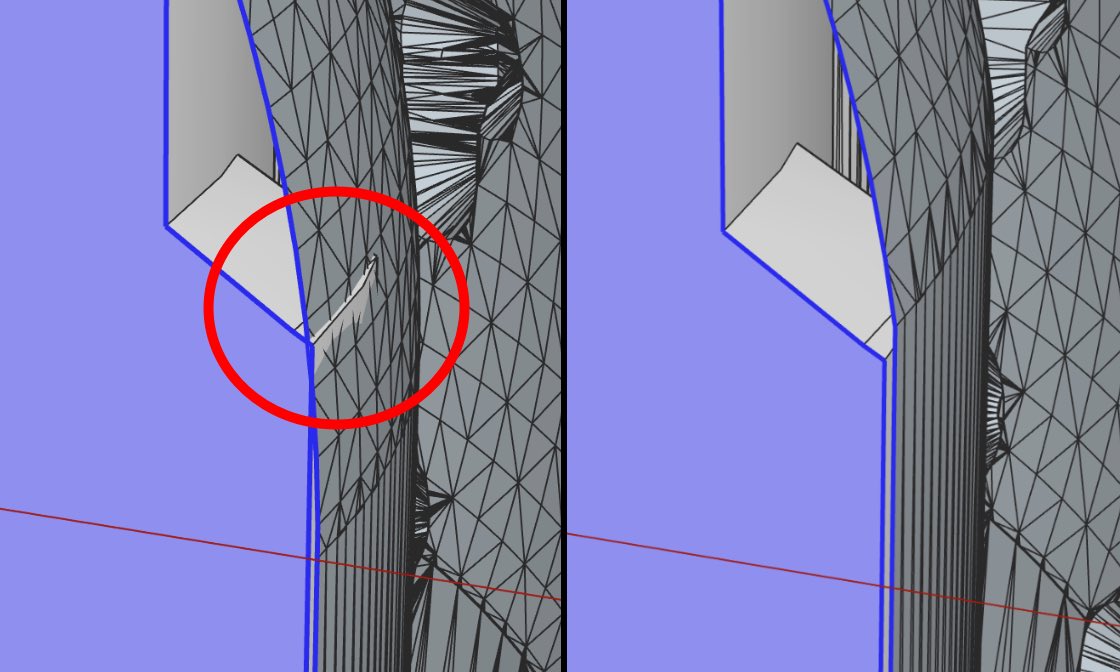

This turned out to be a blessing in disguise, though: I could now test the rotation of the ball on the S1 without worrying about damaging my already broken rotate tape. Turning by hand, it was clearly scraping against the tilt ring somewhere so I modeled it in Sketchup and saw exactly where the problem is:

The solid blue part is the front of the tilt ring, and on the left it's poking through the inside surface of the ball by a literal hair's width, about 0.05 mm. On the right is the updated model with added clearance.

Why didn't I see this until now? Turns out IBM added a bit of wiggle to the ball mount on the Selectric 2. The ball has around 0.5 mm leeway forward and back, which helps it avoid binding if the ball is out of spec. On the S1 that post is fixed and anything that gets stuck between the tilt ring and the ball will jam the ball rotation, leading to all sorts of forces the rotate mechanism wasn't designed for.

And now what

The fixed model looks good! I replaced my rotate tape today, fixed the adjustment so that an IBM ball printed correctly, then put on one of mine fresh from the printer—no sanding or grease. Worked perfectly. :) I am shipping with a smear of grease on the inside of the balls, though, as per IBM recommendation.

Replacements are in the mail or already arrived. If you had an order in the first round you may have received a functional but cosmetically flawed bonus ball from the irregulars bin. It's kinda jerky for me to give you something then say you can't use it, but unfortunately I didn't keep track of who got what so I can't replace those. Instead please use coupon code BETATESTSURVIVOR at checkout for $10 off (expires Nov 1st 2023).

And, as always, please let me know if anything isn't working perfectly and we'll get it sorted out ASAP.